- June 22, 2022

- No Comment

- 277

Where Do People Use Carbon Fiber?

Carbon fiber is used where its lightweight, high tensile strength, high stiffness, high chemical resistance, or ability to conduct electricity are useful or where the look of a carbon fiber weave is desired. There are many reasons to use carbon fiber panels and many ways to use them. Thin crystalline carbon filaments are used to make this strong but light material. Carbon fiber has been used in a lot of different industries because it has a lot of uses. This raw material is great for many things because it is light and strong. Read on to find out more.

Use of Carbon Fiber?

Cars:

Carbon fiber is now used a lot in the automotive world. It used to be something only specialized cars had, but now many sports cars and trucks are starting to have it. It’s a unique part of the design that a lot of people like and even try to copy by wrapping their car in vinyl. Carbon fiber is a good choice because it is strong and durable, not just because it looks good. It is one of the best materials for cars because it is high in strength at the same time.

Aerospace:

One of the first industries to use carbon fiber was the aviation and aerospace industry. It is strong and has a high modulus of elasticity, which makes it a good structural material that can be used instead of aluminum and titanium. Because they are strong for their weight and stiff for their weight, carbon fiber and autoclave composites are mostly used in aerospace.

Every pound of weight saved makes a big difference in how much fuel you use. Because of this, the new Boeing 787 is the most popular passenger jet ever made. Carbon fiber-reinforced composites make up most of the structure of this plane.

Sporting Goods:

Carbon fiber makes a lot of money in the recreational sports market because people are willing to pay more for better performance. Carbon fiber-reinforced composite materials are used to make tennis rackets, golf clubs, softball bats, hockey stick blades, and the shafts of arrows for archery.

As athletes keep looking for ways to get ahead of the competition, carbon fiber gear is becoming more popular. In sports, it helps to have equipment that is light but doesn’t lose strength. A lighter tennis racket makes it easier to swing faster, which makes it easier to hit the ball harder. Serious cyclists also ride bikes made of carbon fiber and wear shoes made of carbon fiber.

Running Shoes:

Carbon fiber is now used to make a stiff plate that is part of the sole of running shoes. Running shoes are made of lightweight foam and have different shoe profiles and heel heights so that they can be used for different types of running. The carbon fiber plate in the shoe doesn’t take up much space. For example, the soleplate of the Brooks Hyperion Elite is only 1mm thick and has a raised spine that ranges from 0.5mm to 2.0mm.

Carbon fiber plates can be found in Nike, Brooks, Saucony, New Balance, and Hoka One shoes. After World Athletics decided that Nike’s Vaporfly ZoomX shoe could be worn at the 2020 Olympics in Tokyo, more shoe companies started to make shoes with carbon fiber.

Most carbon fiber shoes are more expensive than their competing companies, but they cost about the same as other high-end running shoes.

Wind Turbine Blades:

Wind turbine blades are made out of fiberglass. On larger blades (usually over 150 feet long), there is often a structural spar that runs the length of the blade and makes it stiffer. Most of the time, these spars have a thin piece of carbon fiber that makes the structure stiffer.

Carbon fiber gives the structure the stiffness it needs without adding a lot of weight. When wind turbines are made as light as possible, they work best.

Military Applications for Carbon Fiber:

Carbon fiber composites have been used for a while to make naval ships lighter and stronger, especially in the superstructure. They are used in everything from helmets and tent poles to missiles and unmanned aerial vehicles (UAVs) today. Due to its high strength-to-weight ratio, carbon fiber is good for the military because it makes transportation easier and saves energy.

Medicines:

In the medical field, carbon fiber has become an important material. It is very stiff, and X-rays show that it is also radiolucent or see-through. As a result, it has been found to be very helpful in different medical imaging devices. Also, prosthetic limbs made from carbon fiber are strong, lightweight, and easy to wear and use. This is why amputees often use them.

Using Carbon Fiber at Home:

Carbon fiber has a long history of industrial use, but it’s now gaining popularity in the world of home remodeling and do-it-yourself projects. It is an appealing material for furniture, utensils, and even statement clothes. Today, it’s easy to buy pre-built or ready-to-assemble kits, so anyone may have their own carbon fiber accessories manufactured.

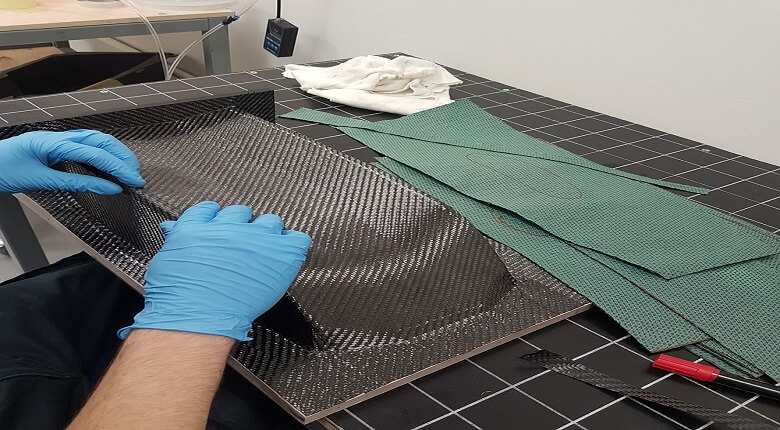

Processes for Fabricating Carbon Fiber Composites:

There are multiple processes available for making carbon fiber components. Some procedures, such as injection molding, are used with a variety of materials, while some are more specific to carbon fiber composites. Process selection is based on factors such as the kind of composite material, the level of detail in component design, and the intended use. The available budget and manufacturing volume should also enter into the decision.

Most carbon fiber fabrication needs some level of molding to form the carbon fiber composite into the desired shape needed for the final application. The procedures for molding can vary in both tools and complexity.

The ideal process for carbon fiber fabrication for your project depends greatly on the volume of components to be produced, your budget, and the eventual use of your parts will be. It is possible to manufacture carbon fiber on your own, but it is recommended that you seek the services of a professional carbon fiber fabricator. Knowing the diversity of carbon fabrication processes available makes it easy to identify the optimal approach for your application.